- NEED HELP? CALL US NOW

- +919995411505

- [email protected]

Instrumentation

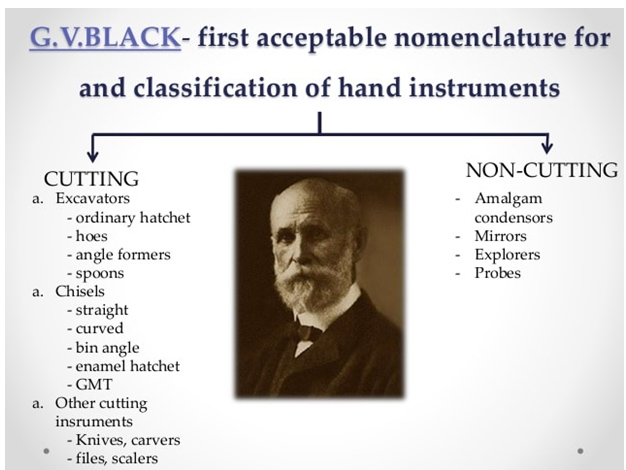

Nomenclature and classification of hand instruments is given by GV Black.

Metals used in the manufacturing of hand instruments are made of two types of steel- carbon steel and stainless steel.

| CARBON STEEL | STAINLESS STEEL | |

| COMPOSITION | Fe-98% C- 1-1.2% Mn-0.2% Si-0.2% |

Fe-81% Cr-18% C-0.6-1% |

| CORROSION RESISTANCE | Very low | High |

| CUTTING EFFICIENCY | High | Low and becomes dull rapidly |

| PHYSICAL PROPERTIES | Stiffer, stronger, harder but more brittle | Hardness is less than carbon steel but it is not brittle |

| EFFICIENCY | Superior at high speeds and wgen cutting enamel | Superior at low speed and when cutting dentin |

INSTRUMENT FORMULA:

- Blade width in tenths of a millimeter

- Angle of the cutting edge with the shaft ( cutting edge angle) when other than at right angles to the the axis of the blade. This is always greater than 50°.

- Length of the blade in millimeters

- Angle of the blade with the shaft (Blade angle) in centigrades or hundredths of a circle. This is always less than 50°.

Eg: 10-85-8-14 indicates:

10- Blade width in tenths of a millimeter ie, 1mm

85- Cutting edge angle in centigrades or hundredths of a circle

8- Length of blade in millineters

14- Blade angle in centigrades

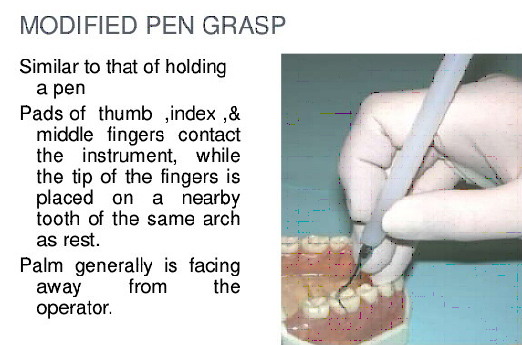

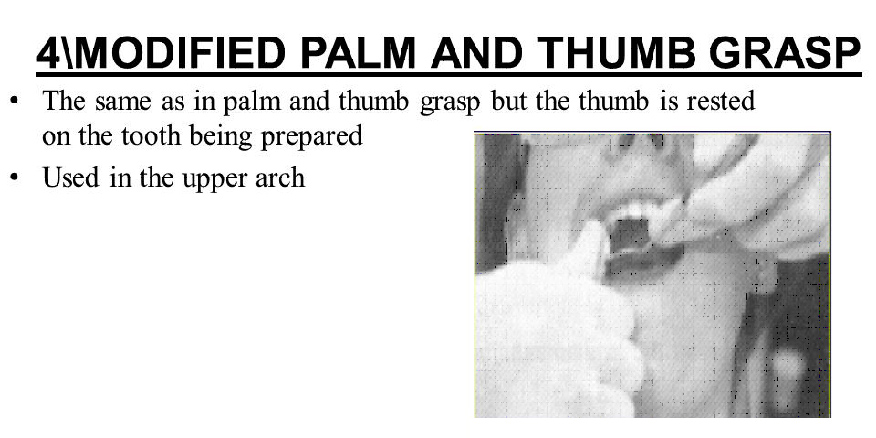

4 types of grasps used with hand instruments:

- Modified pen

- Inverted pen

- Palm and thumb

- Modified palm and thumb

Modified pen grasp permits the greatest delicacy of touch

The materials in use for sharpening stones are:

| Arkansas stone | For sharpening steel instruments |

| Silicon carbide | Industrial abrasives are most commonly used for grinding wheels, sand papers and for sharpening stones |

| Diamond hones | These are small blocks of metal impregnated with diamond particles on the surface. Used for sharpening steel and carbon instruments |

Classification of hand instruments:

Speed ranges:

| Ultra low speed | 200-2000rpm |

| Low speed | 2000-8000rpm |

| Medium high speed | 20,000-45,000rpm |

| High speed | 45,000-1lakh rpm |

| Ultra high speed | Above 1 lakh rpm |

Related posts

April 10, 2025

April 9, 2025

April 4, 2025