- NEED HELP? CALL US NOW

- +919995411505

- [email protected]

A material which is suitable for forming a mould into which molten metal or alloy is cast

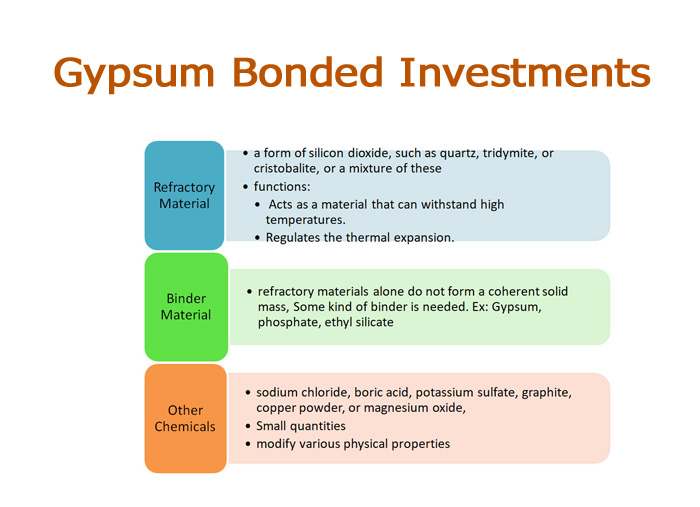

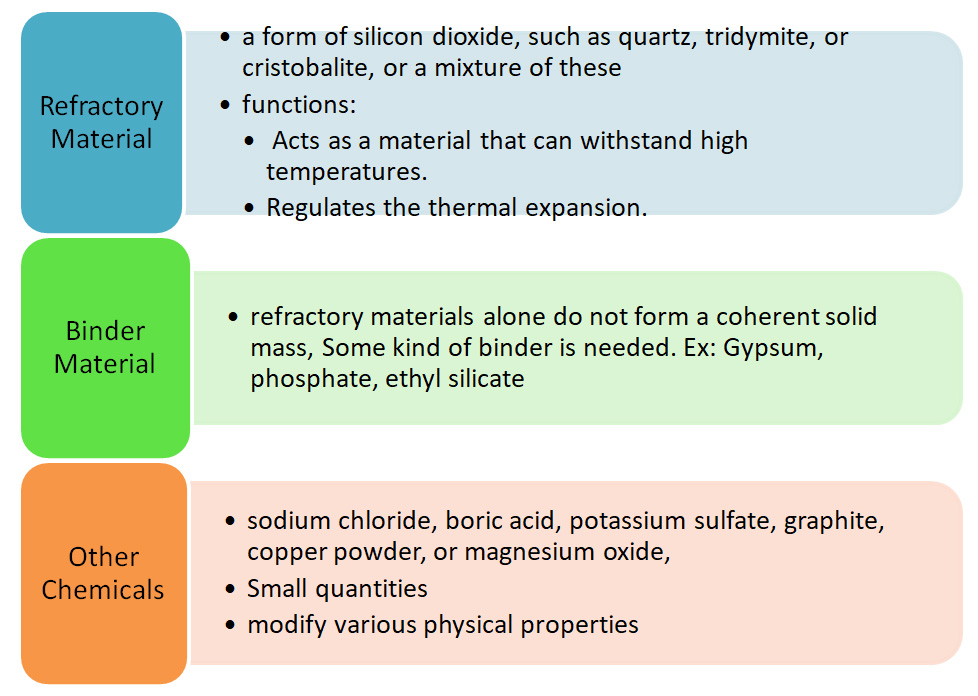

COMPONENTS OF INVESTMENT

PROPERTIES REQUIRED OF AN INVESTMENT

- Easily manipulated

- Sufficient strength at room temperature

- Stability at higher temperatures

- Sufficient expansion: compensate for shrinkage of the wax pattern and metal.

- Porosity: porous enough to permit the air or other gases in the mold cavity to escape.

- Smooth surface: Fine detail and margins on the casting.

- Ease of divestment

- Inexpensive

TYPES OF INVESTMENT

- Based on the nature of Binder

-

- Gypsum bonded investments

- Phosphate bonded investments

- Ethyl silica bonded investments

GYPSUM BONDED INVESTMENTS

ISO (1990) lists 3 types Gypsum Bonded of Investments:- Type I – for inlays and crowns utilizes thermal expansion of the mould.

- Type II – for inlays and crowns utilizes hygroscopic setting expansion.

- Type III – for gold partial denture utilizes thermal expansion.

COMPOSITION

1. Binder : 25% to 35% of α-calcium sulfate hemihydrate is used-To react with water and on hydration binds the silica together.

-To impart sufficient strength to the mould and

-To contribute to the mould expansion by its setting expansion.

-

- Casting gold-containing alloys with melting ranges below 1000 °C

- Material is heated at temperatures sufficiently high

– 200-400 °C: shrink considerably

– 400 °C - 700 °C : slight expansion takes place between

– Above : decomposition and the release of sulfur dioxide causing contamination of alloy

2. Refractory materials:65% to 75% quartz or cristobalite, or a blend of the two(form of silica)- It withstands high temperatures and

- Provides mould expansion by thermal expansion

-

- When heated allotropes of silica changes from α (low room temperature form) to β (high temperature form)

– Phase transformation is called an inversion.

– Causes linear expansion ,overall causing volume expansion

3. A reducing agent: such as powdered charcoal, reduces any oxide formed on the metal. If present should not be heated more than 650ºC4. Modifying chemicals: 2% to 3%: eg. boric acid or sodium chloride to shrinkage on heating.

PROPERTIES

SETTING TIME OF GYPSUM BONDED INVESTMENT

- ADA specification no.2 recommends minimum setting time of 5 mins. and a maximum of 25 minutes.

- The modern investments usually have a initial setting time between 9 to 18 minutes.

NORMAL SETTING EXPANSION

– silica particles probably interfere with the intermeshing and interlocking of the crystals

– thrust of the crystals is outward during growth,

– Soft wax and thin pattern may get distorted,

HYGROSCOPIC SETTING EXPANSION

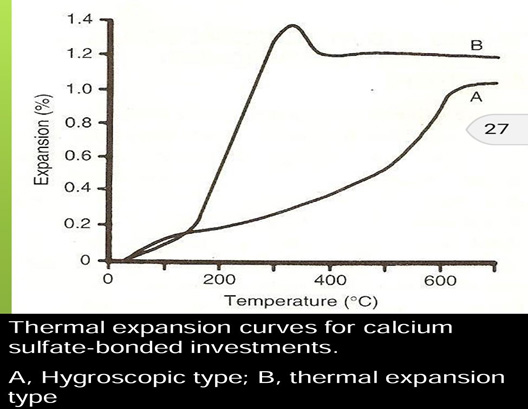

- Expansion when contact with heated water.

- Greater in magnitude than normal setting expansion

- Type II investments : 1.2% - 2.2%

- Directly proportional

– Silica content of the investment

– Water mixed during setting reaction

- Indirectly proportional : size of silica particles

- Thermal expansion of silica must be increased to counterbalance the contraction of the gypsum

- Contraction of the gypsum is entirely balanced when the quartz content is increased to 75%

- Type I: 1% - 1.6%, Type II: - 0% and 0.6% at 500 °C

- It depends on

– Particle size of the quartz,

– Type of gypsum binder: α or β

– Resultant W/P ratio

– Allotropes of quartz : Cristobalite > quartz

THERMAL CONTRACTION– Inversion of the β form to its stable α form at room temperature.

– Contracts to less than its original dimension

EFFECT OF CHEMICAL MODIFIERS

– Increasing the silica content

– reduces the strength of investment

– Small amounts of sodium, potassium, lithium chlorides or boric acid

– eliminates the need for adding silica to cause expansion

STRENGTH

– Adequate to prevent cracking, bulk fracture, or chipping of the mold

– affected by the W/P ratio same way as gypsum.

– It decreases after heating to 700 0C – microcracks

FINENESS

– Fine silica results in a higher hygroscopic expansion

– Also it will give finer details accurately and minimal surface roughness.

MCQs

Gypsum in the investment acts as;A, Filler

B. Binder

C. Refractory

D. Reactor

Answer B